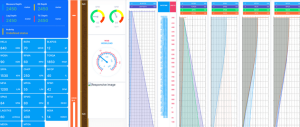

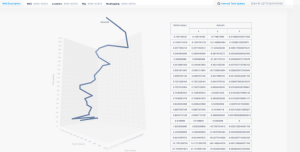

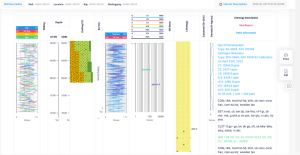

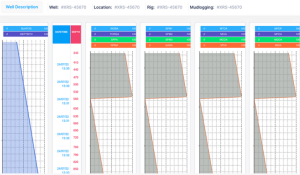

Real time drilling Parameter

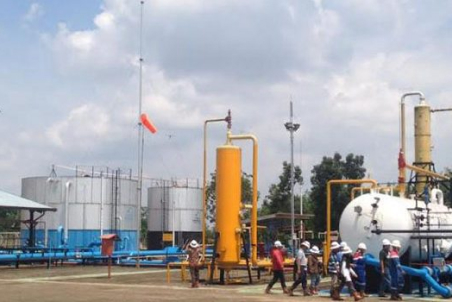

Vital equipment in the drilling industry, providing real-time information from the drilling well. Real-time drilling parameters are data obtained and monitored continuously during the drilling process. This data includes several important factors that provide a deep understanding of the well’s condition and drilling operation at that time.